Modelling and Analysis of BHA and DrillString Vibrations School of Engineering The

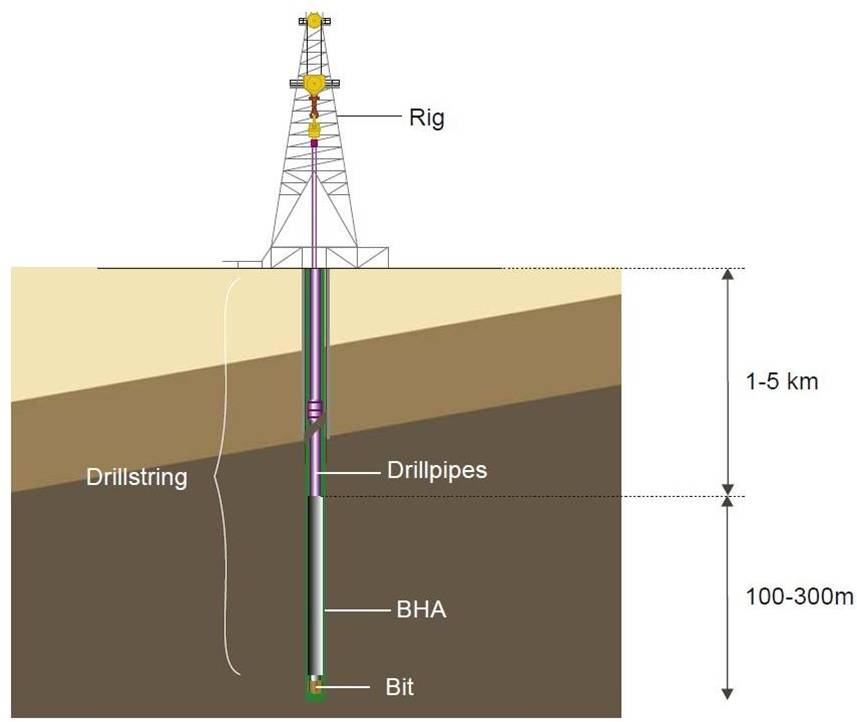

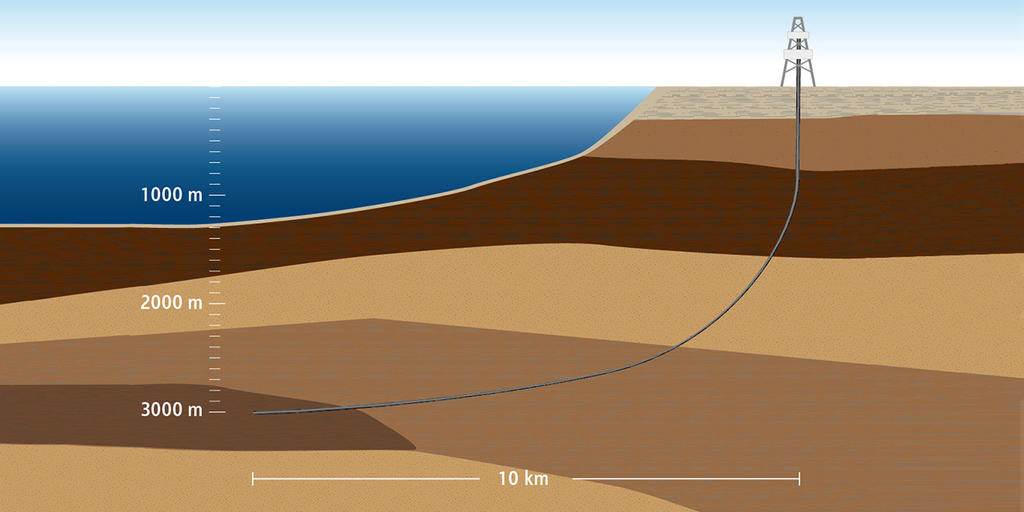

The bottom hole assembly, or BHA, is that portion of the drill string closest to the drill bit. It consists of several components:. Directional drilling refers to any method employed to hit a predetermined subsurface target. One application of directional drilling is the development of offshore fields. Field development costs are reduced by.

Innovation in Directional Drilling

Directional drilling (or slant drilling) is the practice of drilling non-vertical bores. It can be broken down into four main groups: oilfield directional drilling,. Combined, these survey tools and BHA designs made directional drilling possible, but it was perceived as arcane.

MWD LWD Mesa West Directional

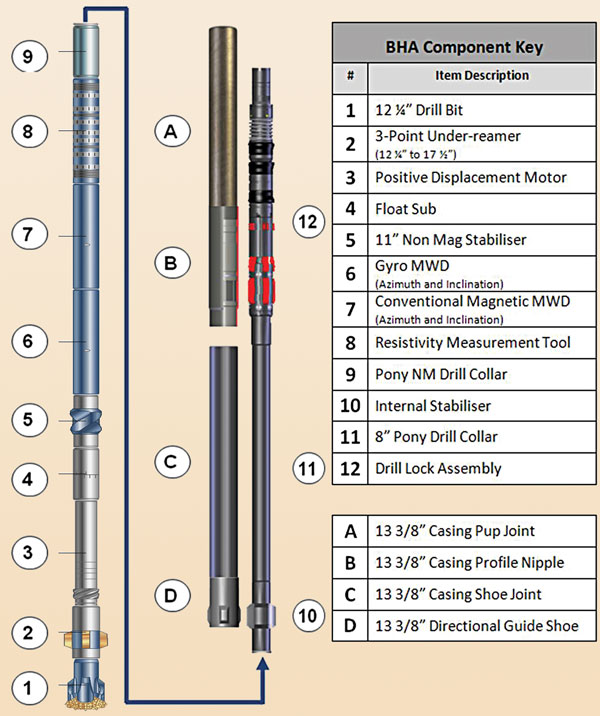

The Bottom Hole Assembly (BHA) is a key component of the drilling system, consisting of various components and tools (including the drill bit itself) which operate at the bottom of the wellbore and physically drill the rock. The BHA is connected to the drilling rig by the drill pipe, an extendable hollow tube which conveys the mechanical and.

Directional Drilling by Rotary Drilling Assembly Drilling Formulas and Drilling Calculations

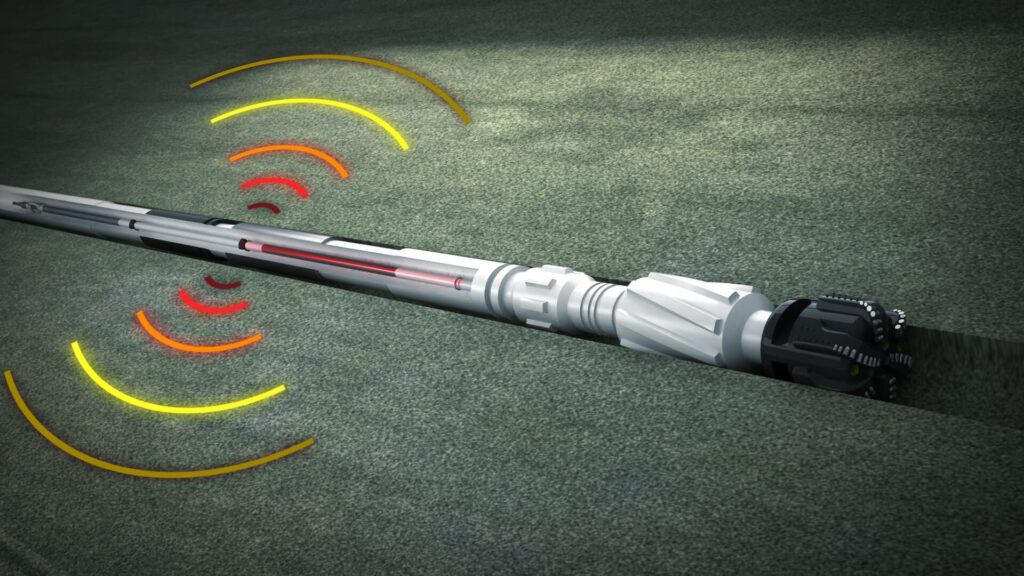

The modeling of the bottomhole assembly (BHA) is an essential problem in directional drilling. Some basic equations for predicting the performance of the BHA are presented in this paper.

Directional Bottom Hole Assemblies

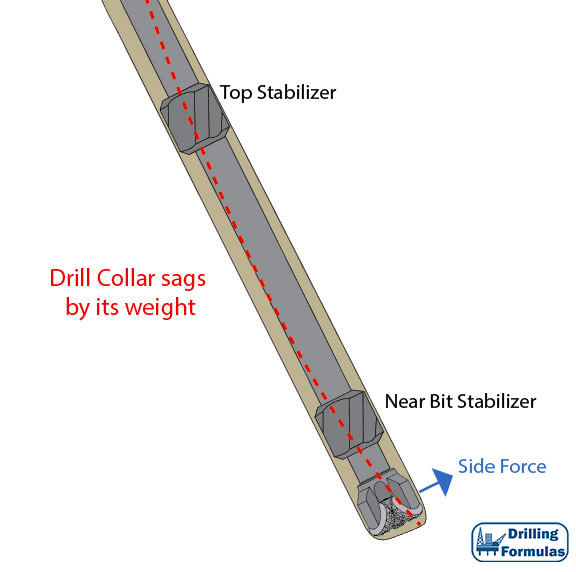

In addition, shock absorbers play an important part in prolonging the service life of the bit and drill pipe. Downhole drilling jars may be needed to unstick the BHA.. The Bottom Hole Assembly BHA design is based upon the requirements of having enough weight transfer to the bit (WOB) to be able to drill and achieve a sufficient Penetration Rate (ROP), giving the Driller or Directional Driller.

Rotary Bottom Hole Assembly In Directional Drilling Drilling Manual

Directional drilling services. Reach and stay in the productive zone faster and more efficiently. SLB provides the expert directional drilling services needed for high-quality wellbores that stay in the "sweet spot"—your optimal production zone. Our proven trajectory control technologies provide precise directional control using our LWD.

A Directional Drilling BHA Presentation Sonatrach Angle Machines

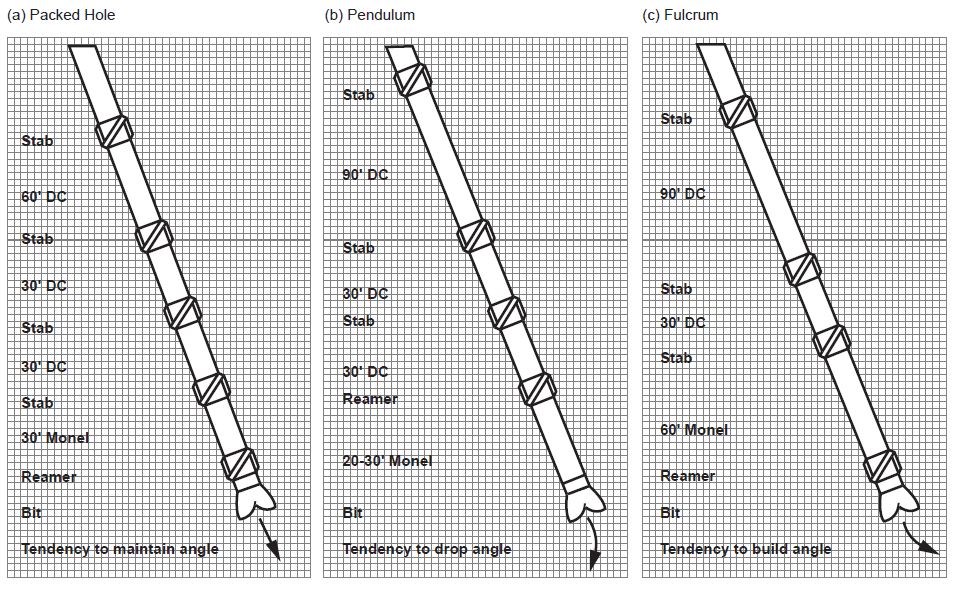

Contents. 1 Factors that determine drilling tendency of the bottom hole assembly (BHA) 1.1 Bit side force. 1.2 Rotary assemblies. 1.3 Building assemblies: fulcrum principle. 1.4 Holding assemblies: packed hole. 1.5 Dropping assemblies: pendulum principle. 2 References. 3 Noteworthy papers in OnePetro.

Assembly bottom directional drilling hole Telegraph

A bottom hole assembly (BHA) is the lowest part of the drill string, extending from the bit to the drill pipe. It is a complex assembly of components that are designed to drill the well, control the wellbore, and provide the driller with information about. The BHA for directional drilling typically consists of a steerable drill bit, drill.

Why better drilling could be the key to a more efficient oil and gas industry Concordia University

Directional BHA for efficient and productive reentry applications. Specifically designed to access additional reserves in thru-tubing reentry drilling applications, the CTDirect coiled tubing directional drilling system enhances reservoir exposure and eliminates the need to remove existing completions or production tubing. The result is.

Directional Drilling Types Drilling Course

The bottom-hole assembly (BHA) is the component of the drill string that includes the core bit, outer core barrel, various subs, and the drill collars. It hangs below the drill pipe and provides weight to the drill or core bit to induce the teeth to penetrate the formation, thereby drilling a hole or recovering core to meet the scientific.

Directional Drilling

This building fulcrum assembly uses a stabilizer (Check Drilling Stabilizer Design & Types) acting as a fulcrum in the directional drilling bottom hole assembly BHA to apply side forces to the bit. The magnitude of that force is a function of the distance from the bit to the tangency point. An increase in bit weight and/or decrease in drill.

Directional casing while drilling applied to improve highangle tophole drilling from producing

Directional Rotary Bottom Hole Assemblies (BHA) Whipstocks; Directional Drilling Survey In Oil & Gas Wells. When drilling a directional well, the actual trajectory of the well must be regularly checked to ensure that it agrees with the planned trajectory. This is done by surveying the position of the well at regular intervals.

a Applications of directional wells single surface location for... Download Scientific Diagram

The modeling of the bottomhole assembly (BHA) is an essential problem in directional drilling. Some basic equations for predicting the performance of the BHA are presented in this paper.

Directional Drilling Optimization Extended Reach Drilling SLB

3 Mud motor selection. A mud motor is a device that converts the hydraulic energy of the drilling fluid into mechanical energy to rotate the bit. It allows you to drill faster, reduce the torque.

Oil well fishing

Directional drilling includes three main specialized applications: extended-reach drilling (ERD), multilateral drilling and short-radius drilling. Operators have used ERD to access offshore reservoirs from land locations, sometimes eliminating the need for a platform.. To build angle, the directional driller uses a BHA with a full-gauge near.

BHAdesign directional drilling

Drilling engineers utilize this type of Bottom Hole Assembly BHA in drilling formations that have severely crooked hole tendencies, such as medium and soft formations, which show a great degree of dipping, fracturing, and variation in strength. In this type of Bottom Hole Assembly BHA, three Stabilizers are included in Zone-1.