Simplify3D Releases Comprehensive Troubleshooting Guide for All Your 3D Printing Issues

Updated Sep 6, 2022 Complete 3D printing troubleshooting guide. All common 3D printing problems and their solutions. Includes both FDM and SLA 3D printing issues.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

Filament Quality: The quality and type of filament used in 3D printing could lead to issues such as warping, bubbles in print, or weak structures. Inherent aspects like filament diameter, moisture content, and material type significantly influence print output. Print Speed: Errors can be introduced if the print speed is too fast or too slow.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech Blog

1. Warping 2. Elephant Foot 3. More First Layer Problems 4. Layer Misalignment 5. Missing Layers 6. Cracks in Tall Objects 7. Pillowing 8. Stringing 9. Under-Extrusion 10. Over-Extrusion 11. Shifting Layers 12. Blocked Bowden Nozzle

3D Printer Troubleshooting The 9 Most Common Problems and Solutions

This would end in a blockage. In this 3D printing issue, raising the height of the nozzle is the simplest solution. Most of the 3D printers would allow you to do this in their system settings, by Z-axis offsetting. You will have to increase the offset value by keeping on adding more to the present value.

5 Common 3D Printing Problems And Their Solutions Blog BulbandKey

Jams? Clogs? Leveling? ERRORS!?The hobby of 3D printing can get frustrating fast! In this video I'll be covering 10+ common problems I've been seeing across.

3D Printing Most common problems for beginners Ram Peripherals 3D Printing & Disc

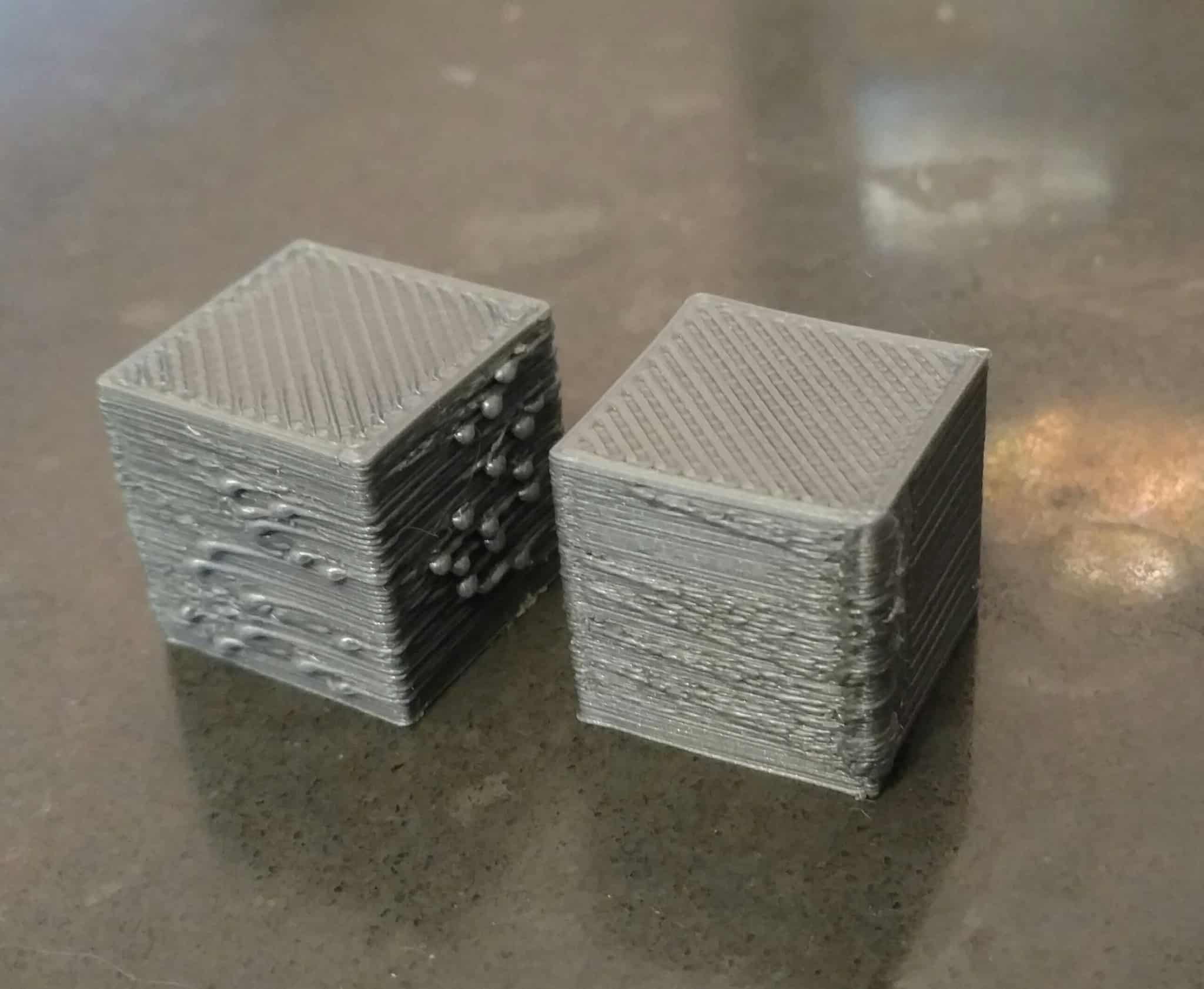

3D printer ghosting, also known as ringing, echoing, and rippling, is a 3D printing issue caused by vibrations that ruins surface finishes with a rippling effect. These ripples and rings affect print quality, often ruining the print's overall aesthetic.

Troubleshooting Guide to 7 Common 3D Printing Problems, our solution. Geeetech

Blog 3D print 🇪🇸 Español 🔥 The definitive guide to solving 3D printing problems by Bitfab 🤬Having problems with your 3D printer? You've come to the right place. In Bitfab we have prepared the definitive guide to solve all your 3D printing problems.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech

1. First Layer Adhesion Problem Check the Bed Levelling Check Bed Temperature Set Optimum Print Speed Set the Fan Speed Adjust Nozzle Height Use External Adhesive Agents Use Bed Adhesion Tools 2. Nozzle Failing to Extrude Material Ensure Priming of Nozzle Adjust Nozzle Height Check for Filament Problems 3. Weak Infill Set Optimum Print Speed

Simplify3D Releases Comprehensive Troubleshooting Guide for All Your 3D Printing Issues

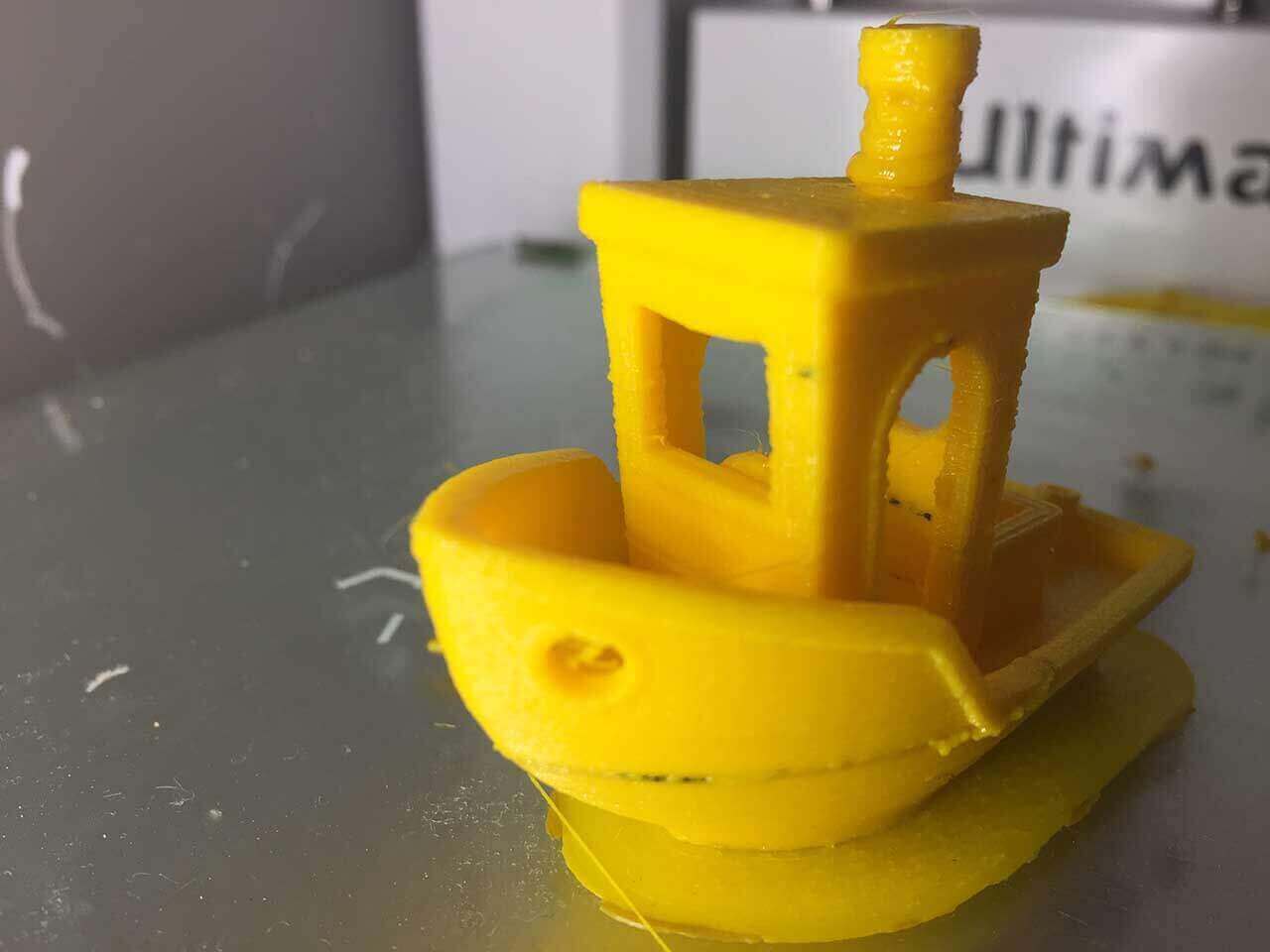

The good news is that most 3D printing problems have simple fixes, and you don't need to go back to school or buy a new printer. This article runs through seven common 3D printing problems with solutions to help you get a handle on your 3D printing. Let's jump in! 1. Under and over extrusion Credit. Under extrusion happens when the 3D.

6 Common 3D Printer Problems and How to Avoid Them Pick 3D Printer

Here's the full scoop on 3D-printing problems, beginning with consumer-grade fused filament fabrication (FFF) 3D printing, which uses more robust materials than resin-based SLA and DLP 3D printing. Then, the industrial applications of 3D printing are examined, focusing on where they're headed for manufacturing, construction, and beyond.

How to Solve Most Common 3D Printing Issues1 Extrusion Problems

9 Common 3D Printing Issues. 1. Extrusion Problems. Extrusion problems are likely the most common problems in this list. This can include not extruding at the start, under extrusion, over extrusion, clogged extruder, stop extruding in the middle, and more. The reasons behind extrusion problems can be the extruder not being primed before you.

3D Printing Troubleshooting Common 3D Printing Problems All3DP

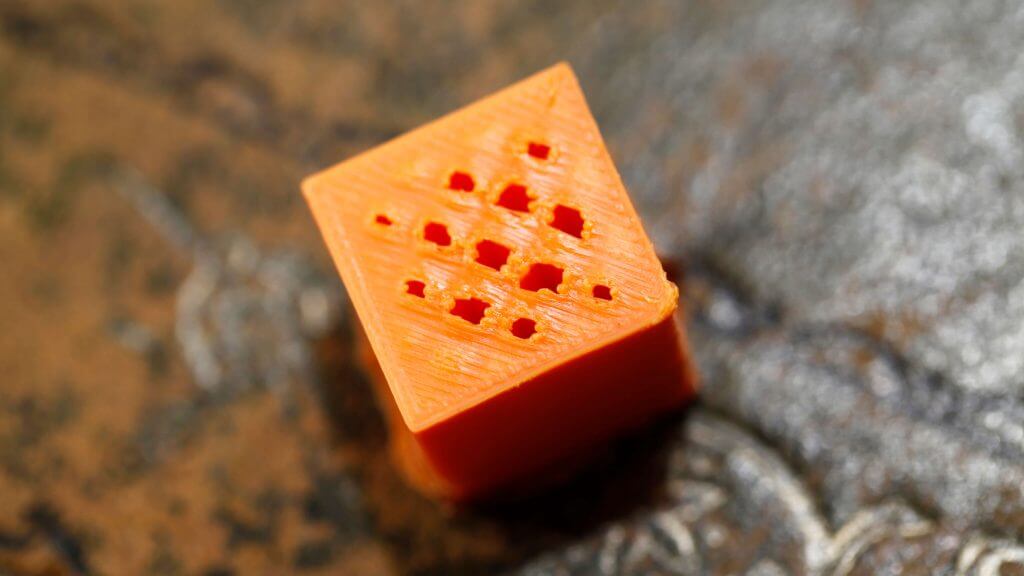

What Are 3D Print Blobs and Zits and Why Are They Bad? Blobs and zits in 3D printing are unwanted bubbles of over-extruded filament on a 3D printed model's shell that should otherwise look smooth and clean, ruining surface finish. Source: Reddit

Troubleshooting Guide to 7 Common 3D Printing Problems, our solution. Geeetech

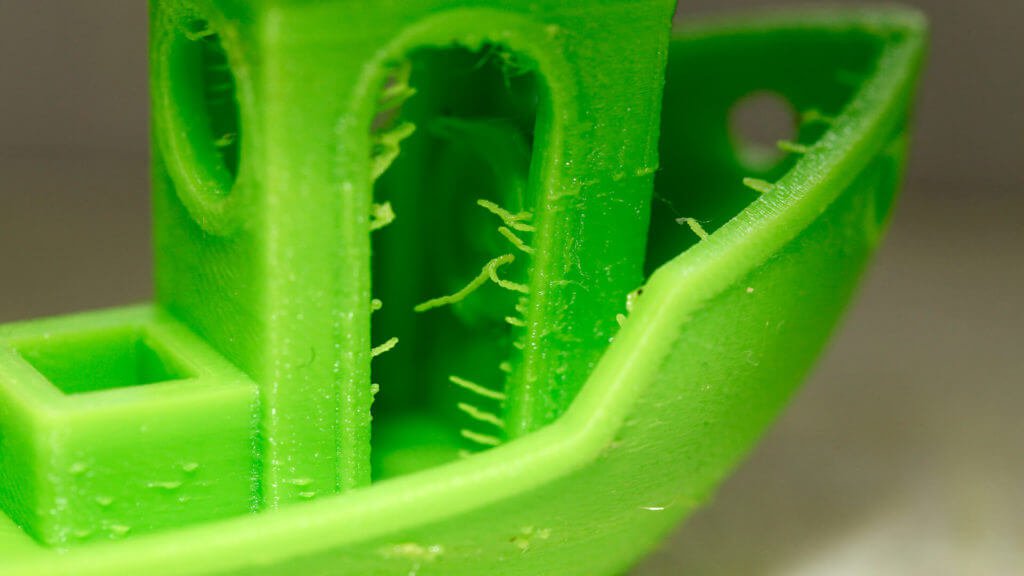

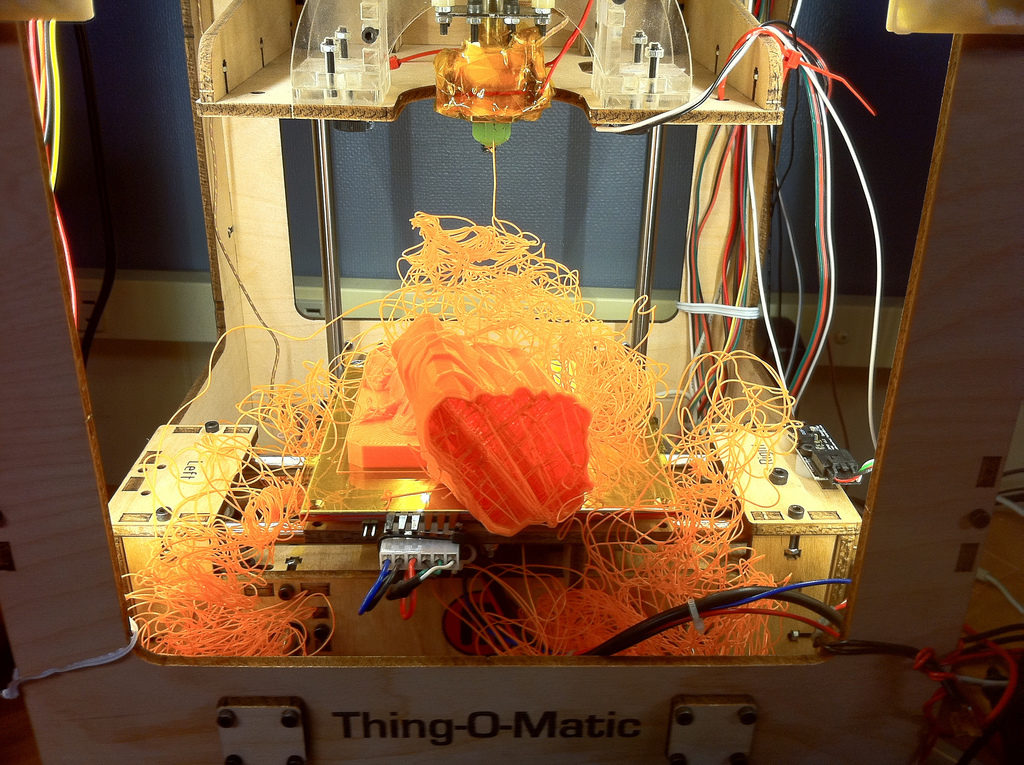

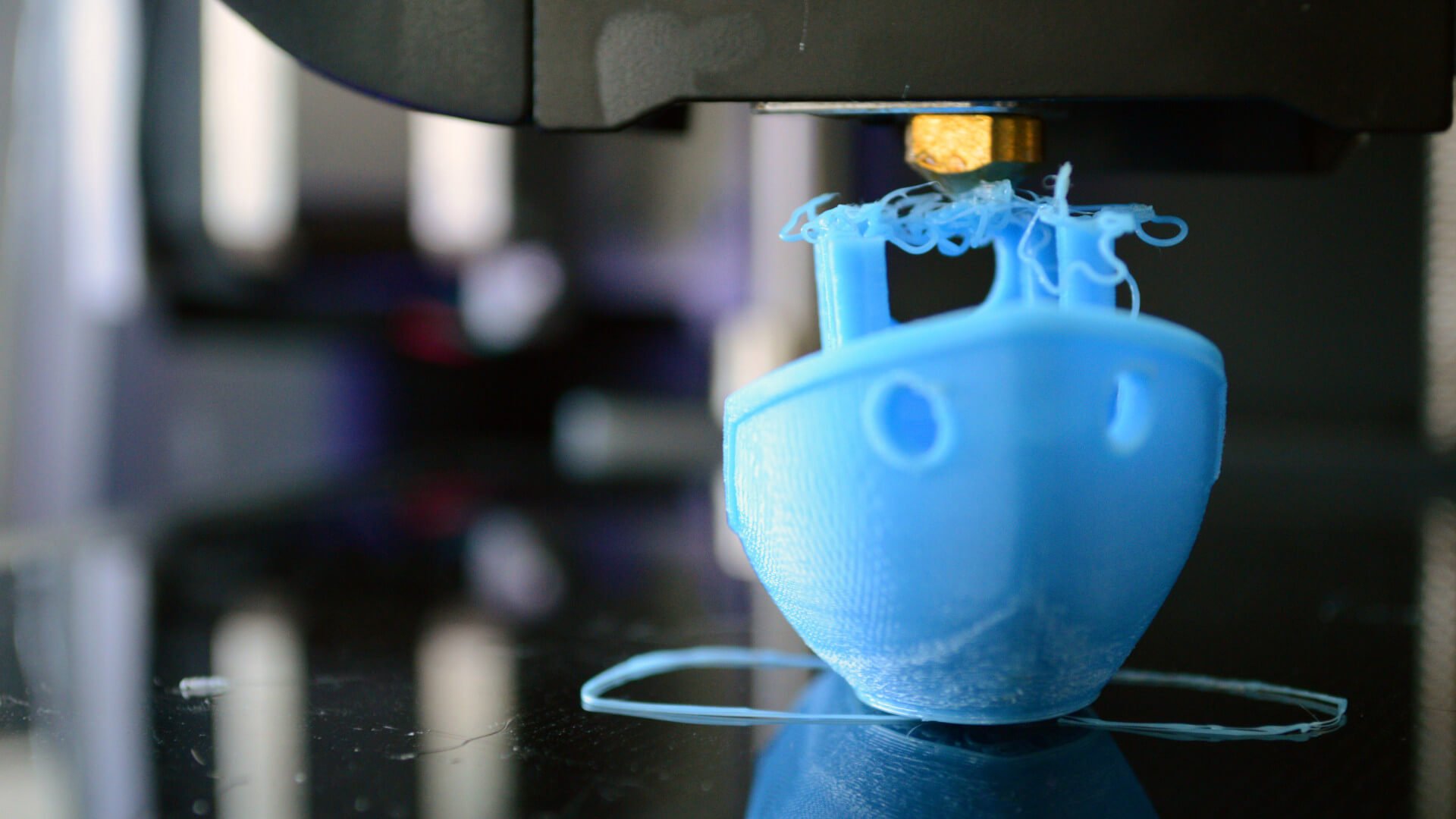

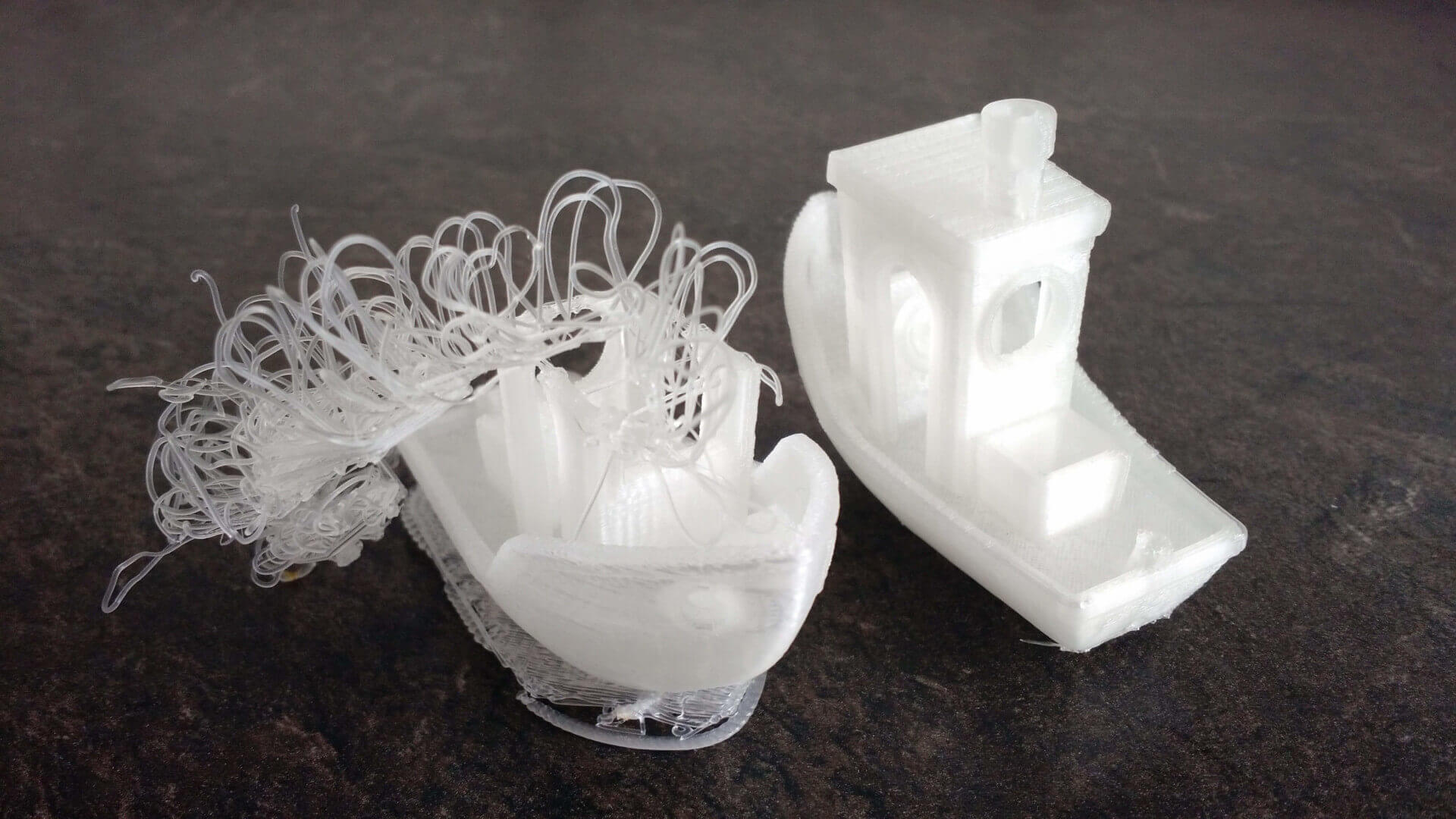

1. "Spider nets", messy surfaces The surfaces are messy on the areas overhanging the plate or have printing errors or rough patches. What's wrong and what to do? Lack of support: If no support is included in the slicing then overhangs might not be printed as they are supposed to. Add support and retry. What is support?

Troubleshooting Guide to 24 Common 3D Printing Problems Part 1 Geeetech

Updated on August 24, 2023 by MatterHackers When printing, unexpected challenges may arise that will need to be resolved in order to complete a successful print. Often times, the appropriate response to a printing issue is not immediately apparent.

Troubleshooting Guide to 19 Common 3D Printing ProblemsPart One Geeetech Blog

Welcome to Part 10 of our comprehensive guide on troubleshooting common problems in 3D printing for beginners.Whether you're using FDM or SLA printing methods, this helpful resource will address the most frequent issues that may arise, such as warping, layer shifting, and inconsistent extrusion.. By understanding the root causes of these challenges and implementing effective solutions, you.

Guía de resolución de problemas de impresión 3D 3D Neworld

October 25, 2023 Tom Bardwell Guides, 3D Printers, 3D Printing Guides Key Takeaways Rough first layer: Caused by nozzle too close to bed. Adjust Z-offset and run calibration test. Gaps between lines: Caused by nozzle too far from bed. Level the bed and increase first layer height and width.