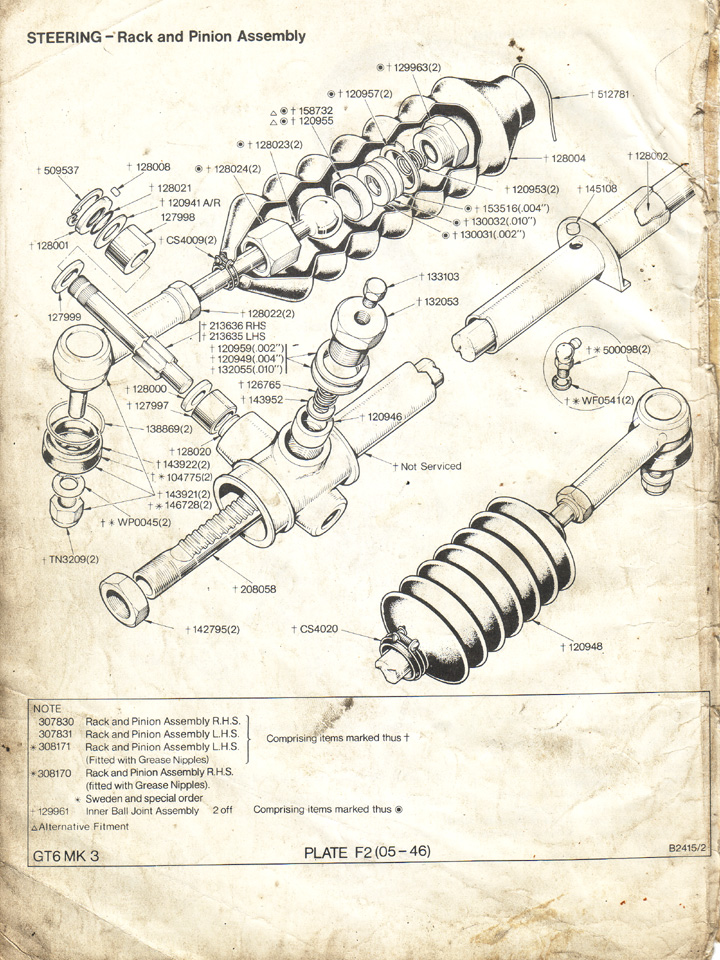

Rack and Pinion Assembly Canley Classics

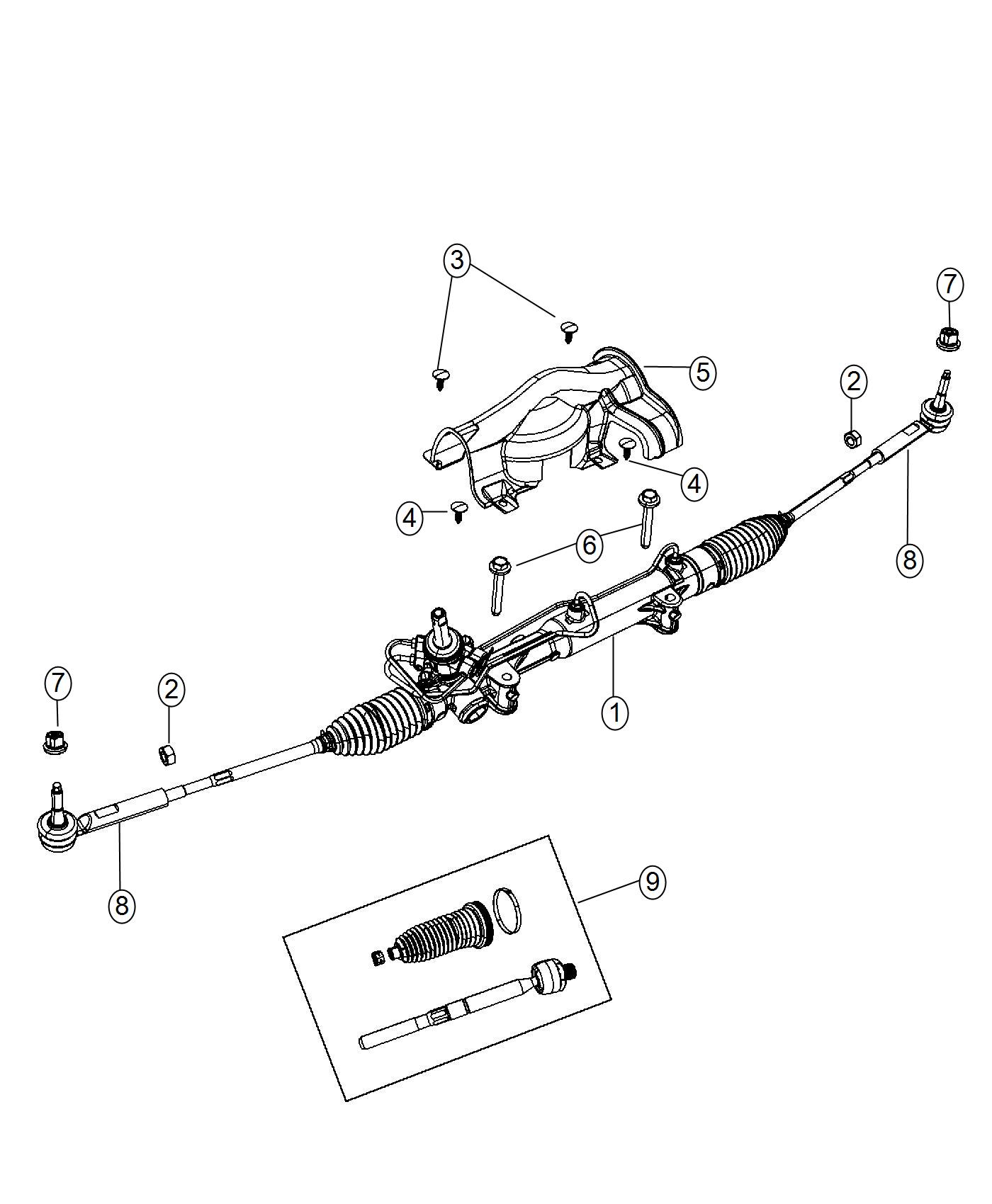

Install the new rack and pinion assembly and loosely install the rack mount bolts. 9. Reinstall the fluid lines, replacing any O-rings with those supplied with the new rack. Reconnect the steering column to the input shaft. Torque the rack mount bolts. 10.

I am replacing the rack and pinion in a 1990 Ford Tempo. what is the o

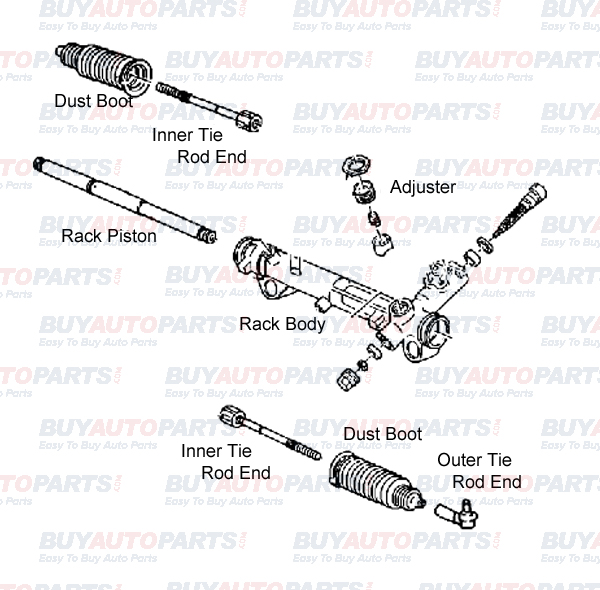

E. Steering Rack, aka "Hydro Steering Box". Most BMWs use rack-and-pinion steering. The pinion is the steering shaft and it meets the steering rack at an angle. Turning the steering wheel turns the pinion shaft and the pinion teeth mesh with the rack teeth to move the rack side-to-side. In this way, power and manual steering racks function the.

27 Rack And Pinion Rebuild Diagram Wiring Database 2020

This type of steering system is commonly used in horse-drawn coaches and trails. This is unsuitable for automobile vehicles because it is unstable at high speeds. Moreover, a center pivot steering arrangement requires a lot of space and because for the whole axle to turn. 3. Ackerman Steering or Side Pivot Steering.

rack and pinion schematic diagram

11 Rack And Pinion Examples: Types, Working, Parts. By Sangeeta Das. Rack and pinion is a mechanical system that is widely used in various applications, ranging from steering systems in automobiles to industrial machinery. It is a simple yet effective mechanism that converts rotational motion into linear motion.

[DIAGRAM] E46 Steering Rack Diagram

Rack and pinion. A rack and pinion is a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack ). Together, they convert between rotational motion and linear motion. Rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate.

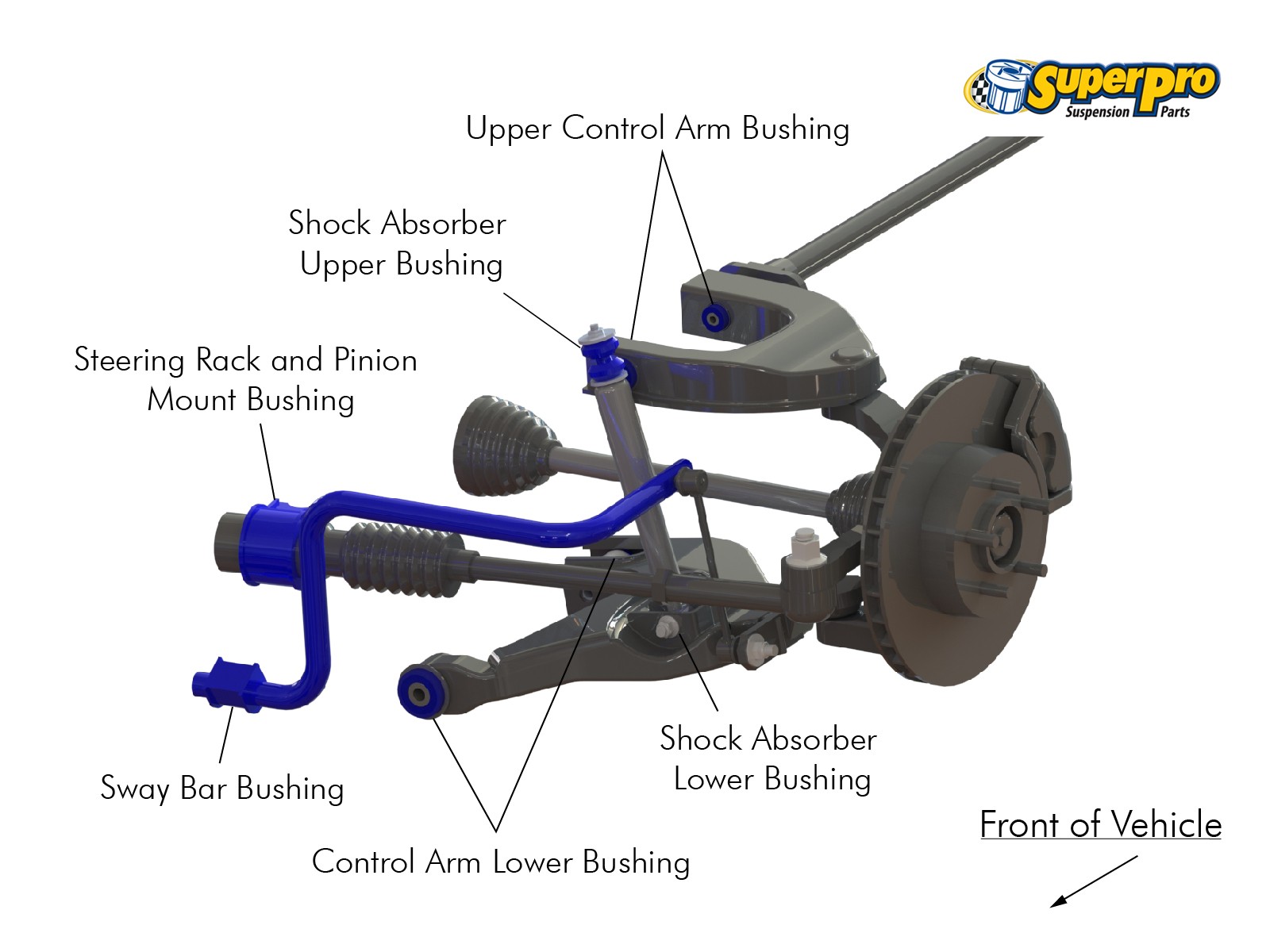

How to Diagnose and Repair Rack and Pinion Bushings RacingJunk News

An aftermarket rack and pinion replacement will typically cost you anywhere from $100 to $500 on parts alone. The price of a new rack-and-pinion steering gear depends on various factors, like the part's brand, quantity, condition, operation, and your vehicle's specifications.

Rack and Pinion Parts Diagram My Wiring DIagram

A rack-and-pinion steering system is prevalent in modern vehicles, enclosed in a metal tube with the rack's ends protruding from it. Connected to the steering wheel, the pinion gear rotates, causing the rack to move. Tie rods at each end of the rack link to the steering arm on the spindle, allowing for responsive and precise control over the.

chrysler Town & Country Gear. Used for rack and pinion. [power rack

The rack and pinion steering system is commonly used in modern vehicles due to its simplicity and effectiveness. It allows for precise steering control, making it easier for the driver to maneuver the vehicle. Additionally, the compact design of the rack and pinion system makes it ideal for use in tight spaces.

Rack And Pinion Parts Diagram

Manual and Hydraulic Power Steering. Our Rack and Pinion units are built to meet or exceed OEM performance. Original designs are scrutinized for potential improvement, and where applicable, design upgrades are implemented to produce a more durable part than the original. All critical components are tested using state of the art testing.

R5154492AA MOPAR Gear. Used for rack and pinion. Remanufactured

The rack-and-pinion gearset does two things: It converts the rotational motion of the steering wheel into the linear motion needed to turn the wheels. It provides a gear reduction, making it easier to turn the wheels. On most cars, it takes three to four complete revolutions of the steering wheel to make the wheels turn from lock to lock (from.

What is a Rack and Pinion

Rack and Pinion Steering Ratio. Moog Parts defines "steering ratio" as the ratio of how far the steering wheel turns to how much the wheels turn. For example, if a 360-degree turn of the steering.

Rack And Pinion Parts Diagram

In the 1930s, German automotive manufacturer BMW invented the rack and pinion steering system, thereby using it in their cars. It was brought up as an alternative to the existing recirculating-ball steering system which was more complex and expensive to build.. American automakers were slow to adopt the technology and started using rack and pinion systems in the Ford Mustang II in the 1970s.

Repair Guides Steering Manual Steering/rack And Pinion

The rack and pinion parts diagram helps to visualize and comprehend the different components involved in this mechanism. One of the key components of the rack and pinion system is the rack. This long, straight bar, usually made of metal, has teeth on one side. The rack is mounted horizontally in the system and is connected to the steering wheel.

Rack And Pinion Parts Diagram Wiring Site Resource

Advantages of rack and pinion steering System. Advantages of rack and pinion type steering gear: 1) Rack & pinion steering gearbox is simple in construction. 2) Economical & easy to manufacture. 3) It is easy to operate with accuracy. 4) Contact between steering rack & pinion is free from play. 5) Internal damping is maintained.

Rack And Pinion Parts Diagram

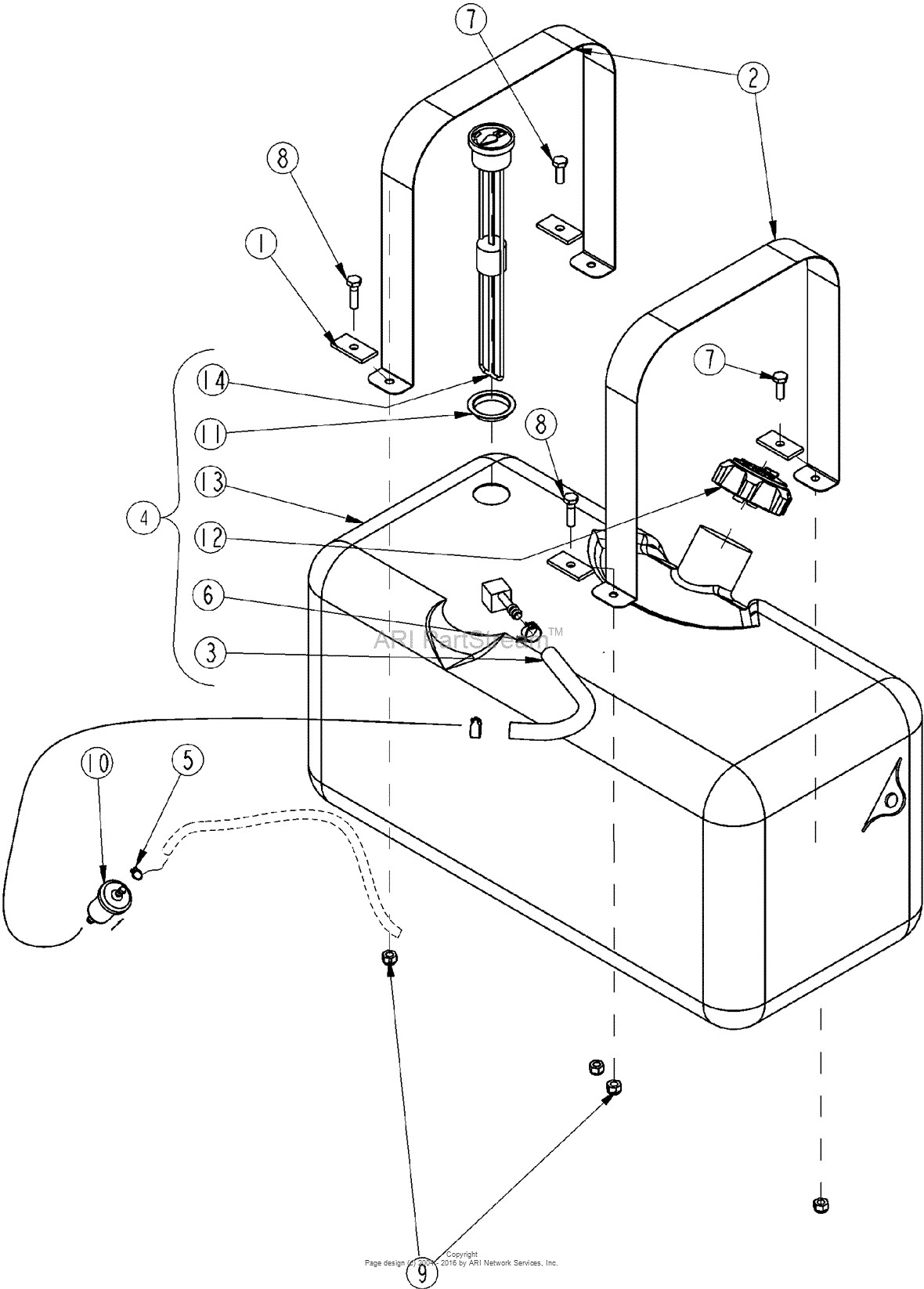

An example of a hydraulic power steering pump diagram. Many vehicles on the road today still have hydraulic power steering. The design uses an engine-driven pump and hydraulic fluid to provide steering assist. A typical hydraulic system includes the following power steering components: Steering Gear (Rack and Pinion Assembly or Worm Gear Box)

Rack And Pinion Repair

Mechanical movement 113, the rack and pinion, works to convert rotational movement into rectilinear motion or vice versa. It's components are a single circular gear (with bearings and a pin) that is stationary, and a moving rack with teeth that engage with the teeth of the gear. The rack is constrained to 2D linear motion by some sort of a track.